perma lubrication systems are extremely flexible in their use for many applications, such as conveyor systems, electric motors, pumps, fans and blowers. This variety also requires diverse mounting solutions for perma’s automated lubrication system.

- Direct mounting is possible for most lubrication points.

- Remote mounting through long grease lines offers additional workplace safety and simplifies maintenance work

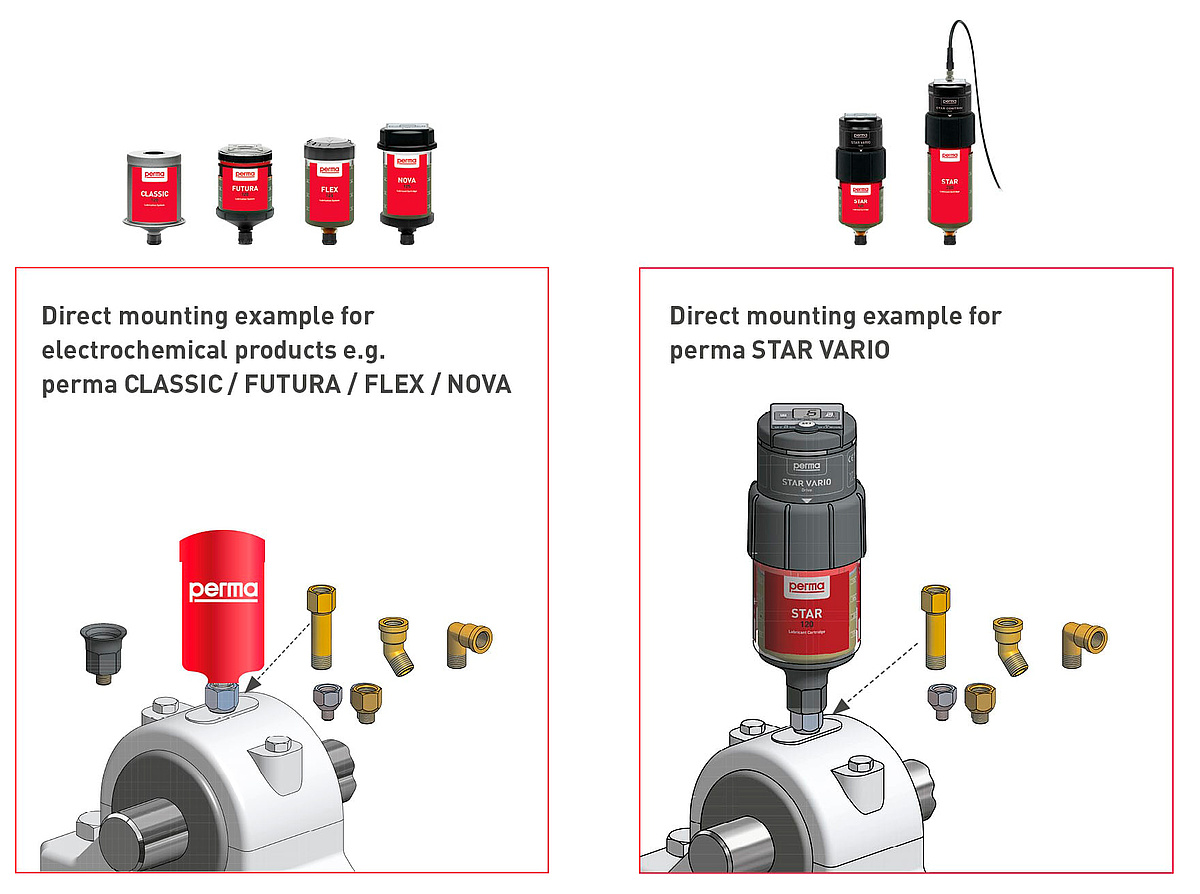

Direct mounting

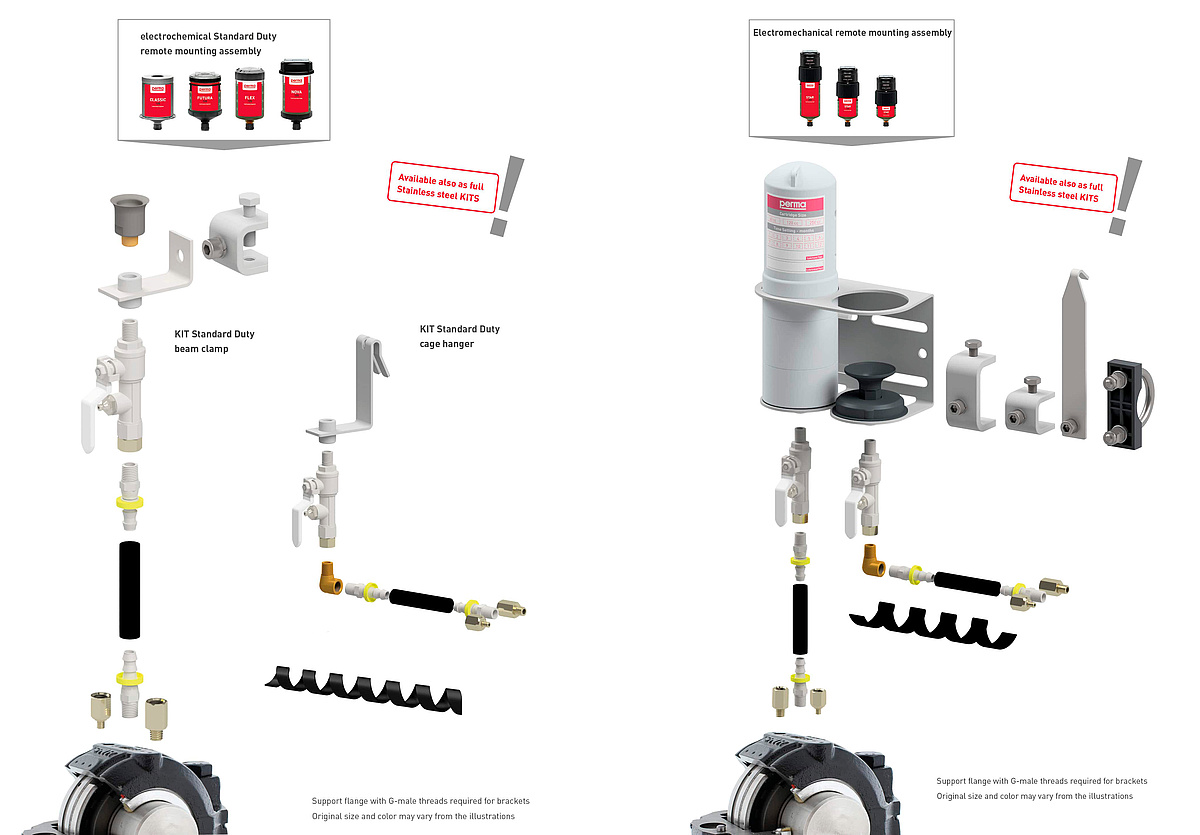

Remote mounting

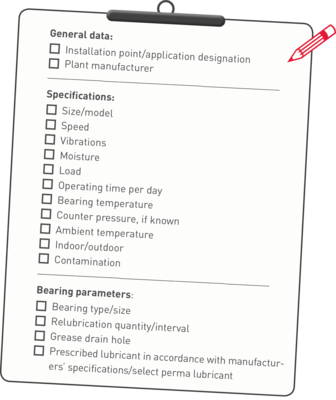

1. Assess lubrication point parameters

A proper direct or remote mounting solution depends on application, environment/conditions and bearing parameters. Use the checklist below to gather information to help determine your specific mounting requirements.

Transfer the information to the perma SELECT APP. You will then receive a recommendation for a suitable perma lubrication system, lubricant and the required setting.

2. Determine mounting solution

With direct mounting, the lubrication system is directly screwed into the lubrication point. However, for many lubrication points it is beneficial to remote mount lubrication systems and thereby guarantee safe access even while the equipment is in operation.

The following questions help guide you to determine the right mounting solution. A “YES” to any of these questions indicates that remote mounting is required.

Is it necessary to remove protective guards or safety cages to access the lubrication point

Is it difficult or unsafe to access the lubrication point while equipment is running?

Is the lubrication point subject to severe vibration or high temperatures which may damage the lubrication system?

Is it necessary to get permits to access lubrication points when in confined spaces or fall protection is required?

Is the lubrication point exposed to excessive amounts of water, process materials or impact from solid material?

3. Choose installation kit

INSTALLATION examples for direct mounting

INSTALLATION examples for remote mounting with grease line

Maximum hose lengths for remote mounting

- 3 ft / 0.9 m for perma CLASSIC / FUTURA

- 6 ft / 1.8 m for perma FLEX / NOVA

- 15 ft / 4.5 m for perma STAR VARIO

- 65 ft / 20 m for perma ULTRA

Limits depend on variables such as grease hose diameter, grease type, ambient temperature and the resistance of the lubrication point itself.

Please consult perma for detailed analysis.

- Click here to find out more on how to install your perma lubrication systems

- Special INSTALLATION KITS and Accessories are available for all perma mounting solutions

- perma also offers a large selection of Greases and Oil to meet your lubrication requirements